api 5l offshore service welded pipe

S. PIPING SOLUTIONS. is stockiest, suppliers & exporters of API 5L Line Pipe, API 5L PSL1 Seamless Pipe, API 5L PSL2 Seamless Pipe, API 5L PSL1 Welded Pipe, API 5L PSL2 Welded Pipe, API ERW Pipe, API HFW Pipe, API SAW Pipe, API LSAW Pipe, API HSAW Pipe, API DSAW Pipe, API 5L Sour Service Pipe, API 5L Offshore Service Pipe.

S. Piping Solutions is a family corporation grounded in hard work, integrity and trust, values integral to all we do. Throughout more than 40 years experience in the international markets, Ashtapad has successfully entered into Mid-east, Australia, America, Africa and Europe markets, providing piping system materials and serving for CNPC, ARAMCO, KOC, CCC, NIOC, CHEVRON, LINDE, PEMEX, FLUOR, NNPC, SONATRACH, TECHNIP, PETROFAC, PETRONAS, PDVSA, SHELL, BP, etc. Reliable can supply API 5L PSL1 & PSL2 Pipe/ ERW/ SAWH/ SAWL/ Coil Tube Linepipe with 3LPE/3LPP/2FBE Coating.

The environment management system of the company is certified according to the requirements of ISO 9001:2008, 14001, 18001, ISO 18001:2007, PED 97/23/EC & Govermment Recognized Export House. Few of the major brands we represent are Arcelor Mittal, Sumitomo, Tenaris, Benteler, Jazeera Steel, Hyundai HYSCO, Arabian Pipes Company, Sandvik, Froch, etc. Our materials are approved by Saudi ARAMCO, SABIC, SHELL, ADNOC, GASCO, PDO, KNPC, KOC, QATAR Gas, OXY, IOOC, SGC etc. It is recognized by major inspection agencies like TUV, DNV, Velosi, Lloyds, Gl, Intertek Moody, BV , SGS, EIL, Jacob H & G, Bax Council, Mecon, PDIL, UDHE, Toyo, ABS, BARC etc.

We are exporting to more than 40 countries like UAE, EGYPT, TURKEY, Singapore, Malaysia, Iran, Iraq, Saudi Arabia, Bahrain, Qatar, Yemen, Kuwait, Argentina, Palestin, Algeria, Italy, Tunisia, Oman, Mauritania, USA, Bangladesh, Lebanon, Canada, Vietnam, Sudan, Syria, Morocco, Libya, Jordon, Indonesia, The Netherland, Brazil, Polland, Korea, USA, UK, Croatia, China, France, Ecuador, South Korea, South America, and many more..

S. Piping Solutions. can supply superior Quality High strength, High Toughness, Homogeneous material and Corrosion Resistant Line Pipes for various special services such as offshore and sour services.

Grades covered by this specification are A25 ,A ,B (and the following "X" Grades), X42, X46, X52, X56, X60, X65, X70, X80. The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.

Chemical composition for offsoure service welded pipe with t ≤ 25,0 mm (0.984 in)

| L245MO or BMO | 0,12 |

0,40 |

1,25 |

0,020 |

0,010 |

0,04 |

0,04 |

0,04 |

f |

-- |

0,19 |

| L290MO or X42MO | 0,12 |

0,40 |

1,35 |

0,020 |

0,010 |

0,04 |

0,04 |

0,04 |

f |

-- |

0,19 |

| L320MO or X46MO | 0,12 |

0,45 |

1,35 |

0,020 |

0,010 |

0,05 |

0,05 |

0,04 |

f |

-- |

0,20 |

| L360MO or X52MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,05 |

0,05 |

0,04 |

e,h |

-- |

0,20 |

| L390MO or X56MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,06 |

0,08 |

0,04 |

e,h |

-- |

0,21 |

| L415MO or X60MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,08 |

0,08 |

0,06 |

e,h |

-- |

0,21 |

| L450MO or X65MO | 0,12 |

0,45 |

1,65 |

0,020 |

0,010 |

0,10 |

0,08 |

0,06 |

e,h |

-- |

0,22 |

| L485MO or X70MO | 0,12 |

0,45 |

1,75 |

0,020 |

0,010 |

0,10 |

0,08 |

0,06 |

e,h |

-- |

0,22 |

| L555MO or X80MO | 0,12 |

0,45 |

1,85 |

0,020 |

0,010 |

0,10 |

0,08 |

0,06 |

e,h |

-- |

0,24 |

Based upon product analysis (see 9.2.4 and 9.2.5) The CE llw limits apply if the C > 0,12 % and the CE pcm limits apply if the < 0,12 %.

b For each reduction of 0,01 % below the specified maximum for C, an increase of 0,05 % above the specified maximum for Mn is permissible, up to a maximum increase of 0,20 %, but up to a maximum of 2.20% for grades ≥ L625 or X90.

c Al total ≤ 0,060 %; N ≤ 0,012 %; Al/N ≥ 2:1 (not applicable to titanium-killed or titanium-treated steel);

d Unless otherwise agreed , Nb + V ≤ 0,06 %.

e Nb + V + Ti ≤ 0,15 %.

f Cu ≤ 0,35 %; Ni ≤ 0,30 %; Cr ≤ 0,30 %; Mo ≤ 0,10 %; B ≤ 0,000 5 %.

g For SMLS pipe, the listed value is increased by 0,03 percentage points, up to a maximum of 0,25 %.

h Cu ≤ 0,50 %; Ni ≤ 0,50 %; Cr ≤ 0,50 %; Mo ≤ 0,50 %; B ≤ 0,000 5 %.

i Cu ≤ 0,50 %; Ni ≤ 0,60 %; Cr ≤ 0,55 %; Mo ≤ 0,80 %; B ≤ 0,000 5 %.

J.4.2 Tensile properties

J.4.2.1 The tensile properties shall be as given in Table J.2.

J.4.2.2 If additional tensile properties are required to be determined at other than room temperature, the acceptance criteria shall be as agreed.

Table J.2 ---Requirements for the results of tensile tests

API 5L Steel Grade |

Weld Seam of HFW, and SAW Pipes |

||||||

Yield Strength.a |

Tensile Strength.a,b |

Ratio a,c Rt0,5 / Rm |

Elongation on 50 mm or 2 in |

Tensile Strength.d |

|||

Minimum |

Maximum |

Minimum |

Maximum |

Maximum |

Minimum |

Minimum |

|

| L245NO or BNO L245QO or BQO L245MO or BMO |

245 (35 500) |

450 e (65 300) e |

415 (60 200) |

655 (95 000) |

0.93 |

f |

415 (60 200) |

| L290NO or X42NO L290QO or X42QO L290MO or X42MO |

290 (42 100) |

495 (71 800) |

415 (60 200) |

655 (95 000) |

0.93 |

f |

415 (60 200) |

| L320NO or X46NO L320QO or X46QO L320MO or X46MO |

320 (46 400) |

520 (75 000) |

435 (63 100) |

655 (95 000) |

0.93 |

f |

435 (63 100) |

| L360NO or X52NO L360QO or X52QO L360MO or X52MO |

360 (52 200) |

525 (76 000) |

460 (66 700) |

760 (110 200) |

0.93 |

f |

460 (66 700) |

| L390QO or X56QO L390MO or X56MO |

390 (56 600) |

540 (78 300) |

490 (71 100) |

760 (110 200) |

0.93 |

f |

490 (71 100) |

| L415QO or X60QO L415MO or X60MO |

415 (60 200) |

565 (81 900) |

520 (75 400) |

760 (110 200) |

0.93 |

f |

520 (75 400) |

| L450QO or X65QO L450QO or X65MO |

450 (65 300) |

570 (82 700) |

535 (77 600) |

760 (110 200) |

0.93 |

f |

535 (77 600) |

| L485QO or X70QO L485MO or X70MO |

485 (70 300) |

605 (87 700) |

570 (82 700) |

760 (110 200) |

0.93 |

f |

570 (82 700) |

| L555QO or X80QO L555MO or X80MO |

555 (80 500) |

675 (97 900) |

625 (90 600) |

825 (119 700)b |

0.93 |

f |

625 (90 600) |

| L625QO or X90QO |

625 (90 600) |

745 (97 900) |

695 (100 800) |

825 (129 800)b |

0.97 h |

f |

- |

| L690QO or X100QO | 690 g (100 100) |

810 g (117 500) |

760 (110 200) |

960 (139 200)b |

0.97 i |

f |

- |

Table J.2 --Requirements for the results of tensile tests

a For intermediate grades, the difference between the specified maximum yield strength and the specified minimum yield strength shall be as given in the table for the next higher grade, and the difference between the specified minimum tensile strength and the specified minimum yield strength shall be as given in the table for the next higher grade, For intermediate grades up to Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000). For intermediate grades greater than Grade L320 or X46 and less than Grade L550 or X80, the tensile strength shall be ≤ 760 MPa (110 200). For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI Units, the calculated value shall be rounded to the nearest 5 MPa. FOr USC units, the calculated value shall be rounded to nearest 100 psi.

b If agreed for pipe in grades equal to or greater than Grade L555 or X80, more stringent maximum tensile strength limits may apply.

c This limit applies for pipe with D >323, 9 mm (12.750 in).

d For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

e For pipe requiring longitudinal testing the yield strength shall be ≤495 MPa (71 800 psi).

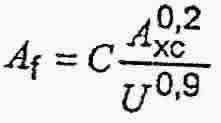

f The specified minimum elongation, Af, on 50mm or (2 in), expressed in percent and rounded to the nearest percent, shall be as determined using the following equation:

Where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

A xc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

-- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2 ( 0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

-- for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter & the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2)

-- for strip test pieces, the lesser of a) 485 mm2( 0.75 in2 ) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2 );

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

g For grades > L625QO or X90QO, Rp0.2 applies.

h Lower Rt0.5 /Rm ratio values may be specified by agrement for L625 or X90.

i For Grades >L625 or X90, Rp0.2 /Rm applies. Lower Rp0.2 /Rm ratio values may be specified by agrement.

J.4.3 Hardness test

For test pieces subjected to a hardness test (see J.8.3.2), the hardness in the pipe body, weld and HAZ shall be

a ) ≤ 270 HV10 or ≤ 25 HRC for Grades ≤ L450 or X65

b ) ≤ 300 HV10 or ≤ 30 HRC for Grades > L450 or X65 > and ≤ L555 or X80.

c ) ≤ 325 HV10 or ≤ 33 HRC for Grades > L555 or X80.

Table J.3 Tolerances for diameter and out-of-roundness

Specified outside diameter D mm (in) |

Diameter Tolerance mm (in) |

Out-of-roundness tolerances mm (in) |

||||

Pipe except the end a |

Pipe end a,b,c |

Pipe except the end a |

Pipe end a,b,c |

|||

SMLS Pipe |

Welded Pipe |

SMLS Pipe |

Welded Pipe |

|||

<60,3 (2.275) |

± 0,5 (0.020) or ± 0,007 5 D, whichever is the greater |

± 0,5 (0.020) or ± 0,007 5 D, whichever is the greater, but maximum of ± 3,2 (0.125) |

± 0,5 (0.020) or ± 0,005 5 D, whichever is the greater, but maximum of ± 1,6 (0.063) |

0,9 (0.036) |

0,6 (0.024) |

|

≥ 60,3 (2.375) to ≤ 610 (24.000) |

0,015 D for |

0,01 D for by agreement |

||||

>610 (24.000) to ≤ 1 422 (56.000) |

± 0,01 D |

± 0,005 D, but maximum of ± 4,0 (0.160) |

± 2,0 (0.079) |

± 1,6 (0.063) |

0,01 D but maximum of 10 (0.4), for by agreement |

0,007 5D but maximum of 8 (0.3), for by agreement |

> 1 422 (56.000) |

as agreed |

|||||

a The pipe end includes a length of 100 mm (4.0 in) at each of the pipe extremities.

b For SMLS pipe, the tolerances apply for t ≤ 25.0 mm (0.984 in). and the tolerances for heavier pipe shall be as agreed.

c For expanded pipe with D ≥ 219,1 mm (8.625 in) and for non-expanded pipe, the diameter tolerance and the out-of-roundness tolerance may be determined using the calculated inside diameter (the specified outside diameter minus two times the specified wall thickness) or measured inside diameter rather than the specified outside diameter.(see 10.2.8.3.)

d For determining compliance to diameter tolerances, the pipe diameter is defined as the circumference of the pipe in any circumferential plane divided by Pi.

Table J.4 -- Tolerance for Wall Thickness

Wall thickness t mm (in) |

Tolerance amm (in) |

< 4,0 (0.157) |

+ 0,6 (0.024) - 0,5 (0.020) |

≥ 4,0 (0.157) to < 10,0 (0.394) |

+ 0,15 t - 0,125 t |

≥ 10,0 (0.394) to < 25,0 (0.984) |

+ 0,125 t - 0,125 t |

≥ 25,0 (0.984) |

+ 3,7 (0.146) or + 0,1 t, whichever is the greater b - 3,0 (0.120) or - 0,1 t, whichever is the greater b |

HFW pipe c,d |

|

≤ 6,0 (0.236) |

± 0,4 (0.016) |

> 6,0 (0.236) to ≤ 15,0 (0.591) |

± 0,7 (0.028) |

> 15,0 (0.591) |

± 1,0 (0.039) |

SAW pipe c,d |

|

≤ 6,0 (0.236) |

± 0,5 (0.020) |

>6,0 (0.236) to ≤ 10,0 (0.394) |

± 0,7 (0.028) |

>10,0 (0.394) to ≤ 20,0 (0.787) |

± 1,0 (0.039) |

> 20,0 (0.787) |

+ 1,5 (0.060) - 1,0 (0.039) |

a if the purchase order specifies a minus tolerance for wall thickness smaller than the applicable value given in this table, the plus tolerance for wall thickness shall be increased by an amount sufficient to maintain the applicable tolerance range.

b For pipe with D ≥ 355,6 mm (14.000 in) and t ≥ 25,0 mm (0.984 in) the tolerance is +12.5% / -12.5% .

c The plus tolerance for wall thickness does not apply to the weld area.

d See 9.13.2 and J 7.2 for additional restrictions.

Table H.3 -- Inspection frequency

longitudi and| Type of Inspection | Type of Pipe | Frequency of Inspection |

| Tensile testing of the pipe body of pipe with D<508 mm (20.000 in) | SMLS, HFW, or SAW | Once per test unit of not more than 100 lengths of pipe with the same cold-expansion ratio a |

| Tensile testing of the pipe body of pipe with D ≥ 508 mm (20.000 in) | SMLS, HFW, or SAW | Once per test unit of not more than 50 lengths of pipe with the same cold-expansion ratio a |

| Tensile testing of the longitudinal or helical-seam weld of welded pipe with 219,1 mm (8.625 in) ≥, D < 508 mm (20.000 in) | HFW, or SAW | Once per test unit of not more than 100 lengths of pipe with the same cold expansion ratio a,b |

| Tensile testing of the longitudinal or helical-seam weld of welded pipe with D ≥, 508 rnm (20.000 in) | HFW, or SAW | Once per test unit of not more than 50 lengths of pipe with the same cold expansion ratio a.b.c |

| Tensile testing of the strip/plate end weld of SAW pipe with D ≥ 219,1 mm (8.625 in) | SAW | Once per test unit of not more than 50 lengths of pipe with the same cold-expansion ratio a.b.c |

| CVN impact testing of the pipe body of pipe with 114,3 mm (4.500 in) ≤ D < 508 mm (20.000) and specified wall thickness as given in Table 22 | SMLS, HFW, or SAW | Once per test unit of not more than 100 lengths of pipe with the same cold-expansion ratio a |

| CVN impact testing of the pipe body of pipe with D ≥ 508 mm (20.000) and specified wall thickness as given in Table 22 | SMLS, HFW, or SAW | Once per test unit of not more than 50 lengths of pipe from the same heat of steel and with the same cold-expansion ratio a |

| CVN impact testing of the longitudinal or helical-seam weld of welded pipe with 114,3 mm (4.500 in) ≤ D < 508 mm (20.000) and specified wall thickness as given in Table 22 | HFW, or SAW | Once per test unit of not more than 100 lengths of pipe with the same cold-expansion ratio a,b |

| CVN impact testing of the longitudinal or helical-seam weld of welded pipe with D ≥ 508 mm (20.000) and specified wall thickness as given in Table 22 | HFW, SAW | Once per test unit of not more than 50 lengths of pipe with the same cold-expansion ratio a,b,c |

| CVN impact testing of the coil/plate and weld of welded pipe with D ≥ 114,3mm (4.500) and specified wall thickness as given in Table 22 | SAW | At least once per 50 coil/plate end welds from pipe with the same cold-expansion ratio a,b,d |

| If agreed, hardness testing of pipe body and of the longitudinal or helical-seam weld and HAZ of welded pipe | HFW, or SAW | As agreed |

| Pipe diameter and out-of-roundness for pipe with D ≤ 168,3 mm (6.625 in) | SMLS, HFW, or SAW | Once per test unit of not more than 100 lengths of pipe |

| Pipe diameter and out-of-roundness for pipe with D < 168,3 mm (6.625 in) | SMLS, HFW, or SAW | Once per test unit of not more than 20 lengths of pipe |

| Non-destructive inspection | SMLS, HFW, or SAW | In accordance with Annex K |

| If agreed, for information purposes only, CTOD test for pipe in Grades ≥ L360 or X52 | SAW | Once; formanufacturing procedure qualification only |

a The cold-expansion ratio is designated by the manufacturer and is derived using the designated before- expansion outside diameter or circumference and the after- expansion outside diameter or circumference. An increase or decrease in the cold-expansion ratio of more than 0,002 requires the creation of a new test unit.

b In addition, pipe produced by each welding machine shall be tested at least once per week.

c For double-seam pipe, both longitudinal weld seams in the pipe selected to represent the test unit shall be tested

d Applies only to finished helical-seam pipe containing strip/plate and welds.

Note:- |

|

Other Specification |

API 5L – A,B, X – 42, 46, 52, 56, |

Special Tube |

Saw Pipes & Steam Pipes |

In Form of |

Round |

In Length of |

Standard |

Value Added Service |

Draw & Expansion as per required Size & Length |

Test Certificate |

Manufacturer Test Certificate |

Tests & Certificates |

• Visual and Dimensional Inspection:

• Mechanical Tests:

• Pipe weld and HAZ tests: • Metallographic Examination

• Non Destructive Inspection:

• Laminations:

Coating: -

The quality level of all Steel Line Pipe, API 5L X46 PSL1 Pipe is guaranteed by a complete internal Quality plan and certificating under ISO-9001, TUV (according to AD 2000-Merkblatt W0/TRD100), API, PED (accordance with Pressure Equipment Directive 97/23/EC), Burst test (Det Norske Veritas), and certainly Lloyds and Stoomwezen. |

We mainly stock the Pipes of following make : Sumitomo Metal - Japan

Nippon Steel - Japan

JFE Steel - Japan

Kawasaki Steel - Japan

Vallourec & Mannesmann - France

Vallourec & Mannesmann - Germany

Vallourec & Mannesmann - Brazil

Salzgitter Mannesmann - Germany

Arcelor Mittal Steel - Romania

Arcelor Mittal Steel - Czech Republic

Tenaris Dalmine - Spain

Tenaris Silcotub - Romania

Tenaris Siderca - Argentina

Tenaris Tamsa - Mexico

Tenaris NKK - Japan

Volzhski - Russia

Nizhnedneprovsky - Ukraine

USS - USA

Welspun - India

Jindal Saw - India

Indian Seamless - India

Maharashtra Seamless – India

Third Party Inspection:

- TUV

- DNV - GL

- VELOSI

- SGS

- Lloyds

- BV

- EIL

- Jacob

- Bax Counsel

- MECON

- PDIL

API-5L-X52 PSL-1 Seamless, ERW, HFW, LSAW, DSAW, HSAW/SSAW (Spiral Welded) Line Pipe

API-5L Grade-B, X-42, X-46, X-52, X-56, X-60, X-65, X-70, X-80 PSL1 PSL2 Line Pipe

API 5L Grade B PSL1 Line Pipes - Available ex-stock

API 5L Grade B PSL1 Sour Service Line Pipes - Available ex-stock

API 5L Grade B PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X42 PSL1 Line Pipes - Available ex-stock

API 5L X42 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X42 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X46 PSL1 Line Pipes - Available ex-stock

API 5L X46 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X46 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X52 PSL1 Line Pipes - Available ex-stock

API 5L X52 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X52 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X56 PSL1 Line Pipes - Available ex-stock

API 5L X56 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X56 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X60 PSL1 Line Pipes - Available ex-stock

API 5L X60 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X60 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X65 PSL1 Line Pipes - Available ex-stock

API 5L X65 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X65 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X70 PSL1 Line Pipes - Available ex-stock

API 5L X70 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X70 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

API 5L X80 PSL1 Line Pipes - Available ex-stock

API 5L X80 PSL1 Sour Service Line Pipes - Available ex-stock

API 5L X80 PSL1 NACE MR-0175 Line Pipes - Available ex-stock

Size Range: -

- Seamless Pipe : ½” to 24”

- ERW Pipe : ½” to 24”

- LSAW/DSAW Pipe : 16” and Above

- HSAW Pipe : 18” and Above

NPS |

SCH 10 |

SCH 20 |

SCH 30 |

SCH STD |

SCH 40 |

SCH 60 |

SCH XS |

SCH 80 |

SCH 100 |

SCH 120 |

SCH 140 |

SCH 160 |

SCH XXS |

1/8" |

|||||||||||||

1/4" |

|||||||||||||

3/8" |

|||||||||||||

1/2" |

|||||||||||||

3/4" |

|||||||||||||

1" |

|||||||||||||

1 1/4" |

|||||||||||||

1 1/2" |

|||||||||||||

2" |

|||||||||||||

2 1/2" |

|||||||||||||

3" |

|||||||||||||

3 1/2" |

|||||||||||||

4" |

|||||||||||||

5" |

|||||||||||||

6" |

|||||||||||||

8" |

|||||||||||||

10" |

|||||||||||||

12" |

|||||||||||||

14" |

|||||||||||||

16" |

|||||||||||||

18" |

|||||||||||||

20" |

|||||||||||||

22" |

|||||||||||||

24" |

|||||||||||||

26" |

|||||||||||||

28" |

|||||||||||||

30" |

|||||||||||||

32" |

|||||||||||||

34" |

|||||||||||||

36" |

|||||||||||||

38" |

|||||||||||||

40" |

|||||||||||||

42" |

|||||||||||||

44" |

|||||||||||||

46" |

|||||||||||||

48" |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: - We can supply heavy thickness of pipe as per clients requirements.

Other Related Grades: -

API 5L Grade B

API 5L Grade X42

API 5L Grade X46

API 5L Grade X52

API 5L Grade X56

API 5L Grade X60

API 5L Grade X65

API 5L Grade X70

API 5L Grade X80

API 5L Grade B PSL 1

API 5L Grade X42 PSL 1

API 5L Grade X46 PSL 1

API 5L Grade X52 PSL 1

API 5L Grade X56 PSL 1

API 5L Grade X60 PSL 1

API 5L Grade X65 PSL 1

API 5L Grade X70 PSL 1

API 5L Grade X80 PSL 1

API 5L Grade B PSL 2

API 5L Grade X42 PSL 2

API 5L Grade X46 PSL 2

API 5L Grade X52 PSL 2

API 5L Grade X56 PSL 2

API 5L Grade X60 PSL 2

API 5L Grade X65 PSL 2

API 5L Grade X70 PSL 2

API 5L Grade X80 PSL 2

API 5L Grade B PSL 1 SEAMLESS

API 5L Grade X42 PSL 1 SEAMLESS

API 5L Grade X46 PSL 1 SEAMLESS

API 5L Grade X52 PSL 1 SEAMLESS

API 5L Grade X56 PSL 1 SEAMLESS

API 5L Grade X60 PSL 1 SEAMLESS

API 5L Grade X65 PSL 1 SEAMLESS

API 5L Grade X70 PSL 1 SEAMLESS

API 5L Grade X80 PSL 1 SEAMLESS

API 5L Grade B PSL 2 SEAMLESS

API 5L Grade X42 PSL 2 SEAMLESS

API 5L Grade X46 PSL 2 SEAMLESS

API 5L Grade X52 PSL 2 SEAMLESS

API 5L Grade X56 PSL 2 SEAMLESS

API 5L Grade X60 PSL 2 SEAMLESS

API 5L Grade X65 PSL 2 SEAMLESS

API 5L Grade X70 PSL 2 SEAMLESS

API 5L Grade X80 PSL 2 SEAMLESS

API 5L Grade B PSL 1 SAW

API 5L Grade X42 PSL 1 SAW

API 5L Grade X46 PSL 1 SAW

API 5L Grade X52 PSL 1 SAW

API 5L Grade X56 PSL 1 SAW

API 5L Grade X60 PSL 1 SAW

API 5L Grade X65 PSL 1 SAW

API 5L Grade X70 PSL 1 SAW

API 5L Grade X80 PSL 1 SAW

API 5L Grade B PSL 2 SAW

API 5L Grade X42 PSL 2 SAW

API 5L Grade X46 PSL 2 SAW

API 5L Grade X52 PSL 2 SAW

API 5L Grade X56 PSL 2 SAW

API 5L Grade X60 PSL 2 SAW

API 5L Grade X65 PSL 2 SAW

API 5L Grade X70 PSL 2 SAW

API 5L Grade X80 PSL 2 SAW

API 5L Grade B PSL 1 ERW

API 5L Grade X42 PSL 1 ERW

API 5L Grade X46 PSL 1 ERW

API 5L Grade X52 PSL 1 ERW

API 5L Grade X56 PSL 1 ERW

API 5L Grade X60 PSL 1 ERW

API 5L Grade X65 PSL 1 ERW

API 5L Grade X70 PSL 1 ERW

API 5L Grade X80 PSL 1 ERW

API 5L Grade B PSL 2 ERW

API 5L Grade X42 PSL 2 ERW

API 5L Grade X46 PSL 2 ERW

API 5L Grade X52 PSL 2 ERW

API 5L Grade X56 PSL 2 ERW

API 5L Grade X60 PSL 2 ERW

API 5L Grade X65 PSL 2 ERW

API 5L Grade X70 PSL 2 ERW

API 5L Grade X80 PSL 2 ERW

API 5L Grade B PSL 1 HFW

API 5L Grade X42 PSL 1 HFW

API 5L Grade X46 PSL 1 HFW

API 5L Grade X52 PSL 1 HFW

API 5L Grade X56 PSL 1 HFW

API 5L Grade X60 PSL 1 HFW

API 5L Grade X65 PSL 1 HFW

API 5L Grade X70 PSL 1 HFW

API 5L Grade X80 PSL 1 HFW

API 5L Grade B PSL 2 HFW

API 5L Grade X42 PSL 2 HFW

API 5L Grade X46 PSL 2 HFW

API 5L Grade X52 PSL 2 HFW

API 5L Grade X56 PSL 2 HFW

API 5L Grade X60 PSL 2 HFW

API 5L Grade X65 PSL 2 HFW

API 5L Grade X70 PSL 2 HFW

API 5L Grade X80 PSL 2 HFW

API 5L Grade B PSL 1 WELDED

API 5L Grade X42 PSL 1 WELDED

API 5L Grade X46 PSL 1 WELDED

API 5L Grade X52 PSL 1 WELDED

API 5L Grade X56 PSL 1 WELDED

API 5L Grade X60 PSL 1 WELDED

API 5L Grade X65 PSL 1 WELDED

API 5L Grade X70 PSL 1 WELDED

API 5L Grade X80 PSL 1 WELDED

API 5L Grade B PSL 2 WELDED

API 5L Grade X42 PSL 2 WELDED

API 5L Grade X46 PSL 2 WELDED

API 5L Grade X52 PSL 2 WELDED

API 5L Grade X56 PSL 2 WELDED

API 5L Grade X60 PSL 2 WELDED

API 5L Grade X65 PSL 2 WELDED

API 5L Grade X70 PSL 2 WELDED

API 5L Grade X80 PSL 2 WELDED

API A25 PSL 1 SEAMLESS

API A25P PSL 1 SEAMLESS

API A25 PSL 1 WELDED

API A25P PSL 1 WELDED

API BR SEAMLESS & WELDED

API X42R SEAMLESS & WELDED

API BN SEAMLESS & WELDED

API X42N SEAMLESS & WELDED

API X46N SEAMLESS & WELDED

API X52N SEAMLESS & WELDED

API X56N SEAMLESS & WELDED

API X60N SEAMLESS & WELDED

API BQ SEAMLESS & WELDED

API X42 Q SEAMLESS & WELDED

API X46 Q SEAMLESS & WELDED

API X52 Q SEAMLESS & WELDED

API X56 Q SEAMLESS & WELDED

API X60 Q SEAMLESS & WELDED

API X65 Q SEAMLESS & WELDED

API X70 Q SEAMLESS & WELDED

API X80 Q SEAMLESS & WELDED

API X90 Q SEAMLESS & WELDED

API X100 Q SEAMLESS & WELDED

API BM WELDED

API X42 M WELDED

API X46 M WELDED

API X52 M WELDED

API X56 M WELDED

API X60 M WELDED

API X65 M WELDED

API X70 M WELDED

API X80 M WELDED

API X90 M WELDED

API X100 M WELDED

API X120 M WELDED

API BNS SEAMLESS & WELDED

API X42NS SEAMLESS & WELDED

API X46NS SEAMLESS & WELDED

API X52NS SEAMLESS & WELDED

API BQS SEAMLESS & WELDED

API X42QS SEAMLESS & WELDED

API X46QS SEAMLESS & WELDED

API X52QS SEAMLESS & WELDED

API X56QS SEAMLESS & WELDED

API X460QS SEAMLESS & WELDED

API X65QS SEAMLESS & WELDED

API X70QS SEAMLESS & WELDED

API BMS WELDED

API X42MS WELDED

API X46MS WELDED

API X52MS WELDED

API X56MS WELDED

API X60MS WELDED

API X65MS WELDED

API X70MS WELDED

API BNO SEAMLESS & WELDED

API X42NO SEAMLESS & WELDED

API X46NO SEAMLESS & WELDED

API X52NO SEAMLESS & WELDED

API BQO SEAMLESS & WELDED

API X42 QO SEAMLESS & WELDED

API X46 QO SEAMLESS & WELDED

API X52 QO SEAMLESS & WELDED

API X56 QO SEAMLESS & WELDED

API X60 QO SEAMLESS & WELDED

API X65 QO SEAMLESS & WELDED

API X70 QO SEAMLESS & WELDED

API X80 QO SEAMLESS & WELDED

API X90 QO SEAMLESS & WELDED

API X100 QO SEAMLESS & WELDED

API BMO WELDED

API X42 MO WELDED

API X46 MO WELDED

API X52 MO WELDED

API X56 MO WELDED

API X60 NO WELDED

API X65 MO WELDED

API X70 MO WELDED

API X80 MO WELDED